How PVC Pipe Caps Prevent Costly Repairs In Construction

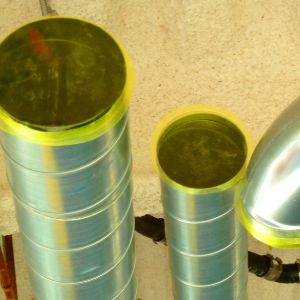

Preventing costly repairs in construction is a priority for industry professionals, and PVC pipe caps play a critical role in achieving this objective. When PVC pipes are left exposed on a construction site, they can be susceptible to a host of issues, from dust accumulation and contamination to physical damage. SmartGuard offers protection solutions, including pipe caps. These offer an efficient and cost-effective shield against these potential problems, ensuring the longevity and functionality of the project.

What Are PVC Pipe Caps?

PVC pipe caps are essential components in construction, serving as protective covers for exposed pipe ends. Made of high-quality, recyclable PVC, they block the intrusion of the site’s concrete debris, dust, and other contaminants, which could otherwise compromise the integrity of the pipes. In construction environments, pipes are often left open for extended periods, making them vulnerable to harm and increasing the risk of costly delays. They also help support OSHA safety standards by minimizing hazards.

How PVC Pipe Caps Reduce Construction Costs

Preventative measures like using PVC pipe caps directly influence cost-efficiency in construction projects. When pipes are damaged, it necessitates repairs or replacements, leading to increased expenses. By using PVC pipe caps, construction workers and project managers can avoid these unnecessary costs. Moreover, prevention of contamination and blockage significantly reduces the likelihood of unforeseen maintenance.

Shielding Pipes From Physical Damage

The risk of physical damage to pipes is high on bustling construction sites, where heavy machinery and equipment are in constant motion. Pipes left exposed are prone to cracking, chipping, or complete breakage upon impact. Pipe caps act as a buffer, mitigating damage and preserving pipe integrity. This protection is pivotal in preventing the costs associated with repairing or replacing damaged pipes.

Delaying The Onset Of Corrosion

Exposing metal pipes without protection accelerates the corrosion process, particularly in environments with high humidity or chemical exposure. PVC pipe caps create a waterproof barrier that keeps corrosive elements out, extending the lifespan of the pipes. By delaying corrosion, project owners can maintain infrastructure integrity while avoiding premature pipe repair expenses.

Application Versatility Of PVC Pipe Caps

SmartGuard’s PVC pipe caps offer unmatched versatility for a range of construction applications. Designed in various sizes and styles, these caps can be customized to fit the specific needs of any project, ensuring reliable protection and enhanced system durability. Here are some key applications:

- Temporary Piping Installations: Secure exposed pipe ends during the construction phase.

- Drainage and Sewer Systems: Protect open drainage lines from debris and contamination.

- Exposed Plumbing Lines: Safeguard plumbing conduits until final installation.

- Site Infrastructure: Enhance the durability of utility and irrigation systems on job sites.

Taping vs. Capping PVC Pipes

When it comes to safeguarding exposed pipes on construction sites, two methods are commonly used: taping and capping. Taping offers a quick, temporary seal that’s easy to apply, but degrades rapidly under harsh conditions and requires frequent reapplication However, capping, though requiring proper installation, provides a durable, robust, and low-maintenance barrier that meets OSHA standards by effectively protecting against contaminants and physical damage.

FAQs: Common Queries About PVC Pipe Caps

What Size Do PVC Pipe Caps Come In?

PVC pipe caps are manufactured to accommodate a wide range of pipe dimensions, from small domestic plumbing to large industrial applications.

Are PVC Pipe Caps Reusable?

Yes, many PVC pipe caps are durable enough to be reused across multiple projects, making them a cost-effective choice.

How Do PVC Pipe Caps Contribute To Safety?

By preventing contamination and physical damage, these caps ensure pipes function optimally, thereby upholding safety standards on site.

Where Can PVC Pipe Caps Be Used?

They are used across various construction sectors, including residential, commercial, and industrial establishments.

The Pros & Cons Of PVC Pipe Caps

While PVC pipe caps offer numerous benefits, it is also critical to weigh them against any potential drawbacks to make informed decisions:

- Pros: Affordable, easy to install, versatile in applications, recyclable, robust against environmental damage.

- Cons: May degrade if exposed to extreme UV levels without additional protection, can be limited to certain types of pipes.

Making Informed Choices in Construction

Choosing the right materials and protective measures is integral to the success of any construction project. PVC pipe caps represent a small yet significant investment that yields substantial returns in maintenance savings and operational efficiency. By informing themselves about the benefits and applications of PVC pipe caps, construction professionals can make choices that align with both budgetary constraints and project goals.

SmartGuard, Your Partner In Efficient Construction Protection

Embrace the advantages of preventative measures and reduce unforeseen expenses in your construction projects with durable PVC pipe caps. For those in need of reliable and high-quality pipe protection solutions across the USA, SmartGuard is committed to meeting the comprehensive needs of construction professionals, ensuring your ventures are protected, efficient, and successful. Contact us today for more information on how our innovative products can safeguard your projects.